A duplex system is formed by painting or powder coating over hot-dip galvanized or thermal spray coated steel. Used for decades as a means to enhance corrosion protection, the synergy between the two systems provides protection far superior to either system used independently. Common examples in the market place are ColorGalv® or COLORZINQ®.

Duplex coating systems utilizing thermal sprayed zinc or its alloys have been in use on bridge structures in Europe for over 50 years. 40-year lifespans of zinc/aluminum alloy thermal sprayed duplex coating systems have been documented on coastal bridges in Norway. The AASHTO (American Association of State Highway Officials) Study of bridge systems has rated a thermal sprayed zinc aluminum coating, top-coated with an epoxy/polyurethane system for 25 years to first touch-up.

At Inter-City Contracting we can provide duplex coating systems in one of 2 ways:

- We can prepare your already galvanized materials and apply a 2- or 3-coat high performance coating system, typically an epoxy primer/mid-coat and an aliphatic polyurethane topcoat.

- We can prepare your un-coated steel, thermal spray a metalized coating of zinc, aluminum or their alloys and apply a 2- or 3-coat high performance coating system to the metalizing.

These equivalent methods both provide unparalleled corrosion protection in comparison with other high performance coatings systems.

How Duplex Coatings Work

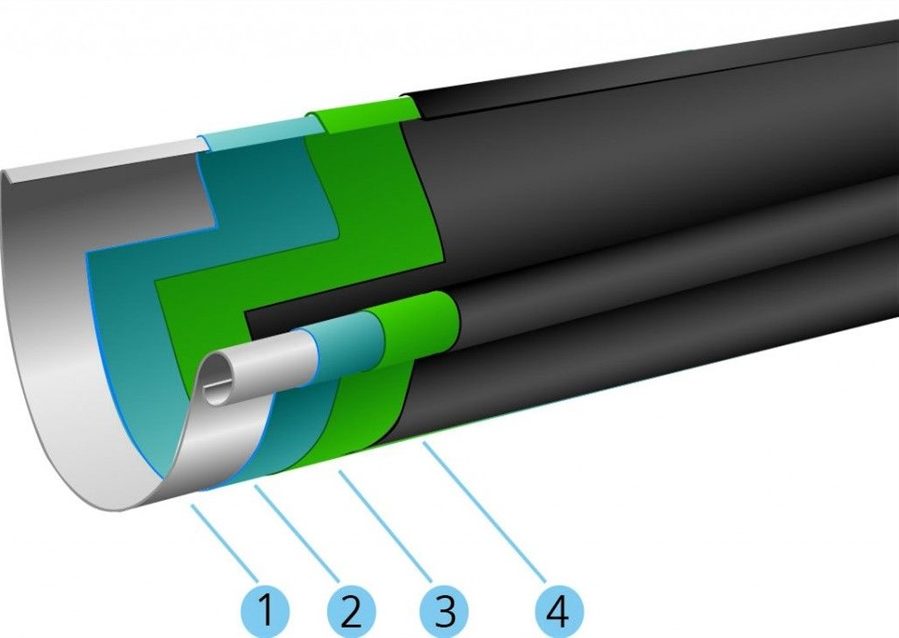

Coatings Layers

- Galvanizing or Thermal-Sprayed Metal

- Primer/Sealer

- Mid-Coat

- Finish Coat

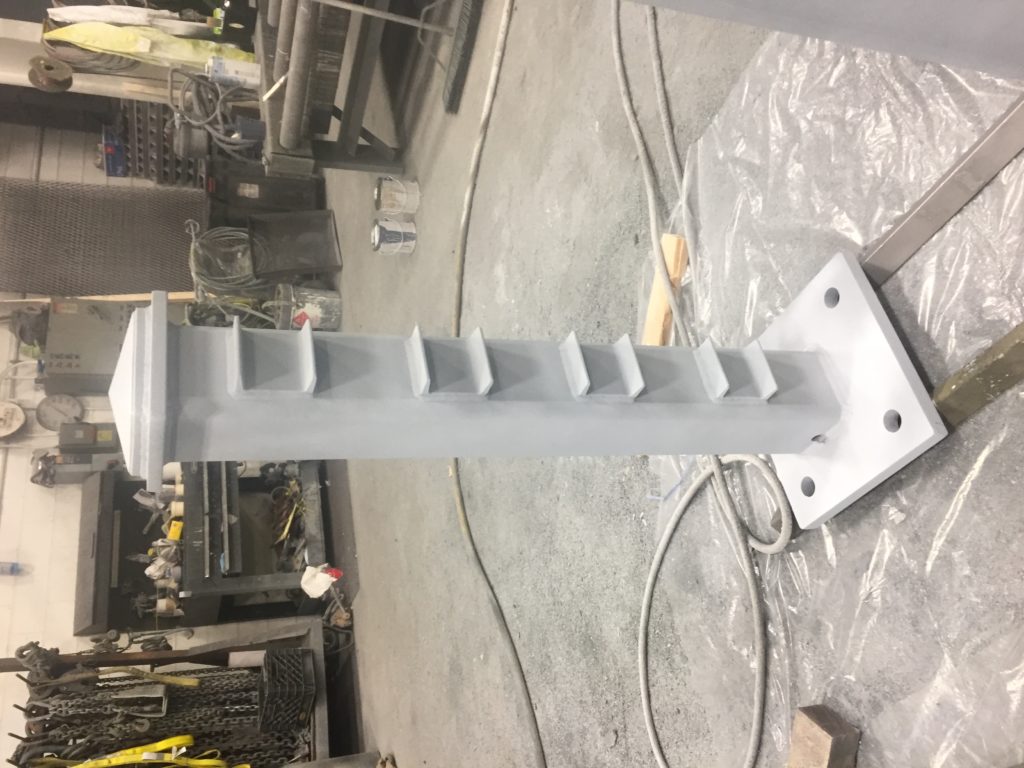

The Application Process

Raw

Abrasive Blasted

Thermal Sprayed

Sealed/Stripe Coated

Finish Coated

blasted galvanizing

touch-up galvanizing

primed

finish coated

Click here for more information about duplex coatings systems.