Metallizing or Thermal Sprayed Coating is the process of applying zinc, aluminum or its alloys and other composites to steel and iron as molten liquid metal to provide corrosion protection.

This process is used extensively in the corrosion protection industry in many environments and has been shown to greatly extend the lifespan of steel and iron structures. Thermal spray is one of the most common foundations of duplex coating systems and have been in use on bridge structures in Europe for over 50 years. 40-year lifespans of zinc/aluminum alloy thermal sprayed duplex coating systems have been documented on coastal bridges in Norway. The AASHTO (American Association of State Highway Officials) study of bridge systems has rated a thermal sprayed zinc/aluminum coating, top-coated with an epoxy /polyurethane system 25 years to first touch-up and has gained in popularity in the United States in the last 20 years.

If you have a project that requires the ultimate in corrosion protection consider using metallizing to improve your current corrosion prevention paint system and as an alternative for galvanizing on large structures that are too big or irregular shaped for galvanizing to be practical.

Thermal sprayed materials available:

For Corrosion Protection

- 100% zinc

- 85% zinc/15% aluminum

- 100% aluminum

For Appearance/Aesthetics

- Copper

- Bronze

- Brass

- Stainless Steel

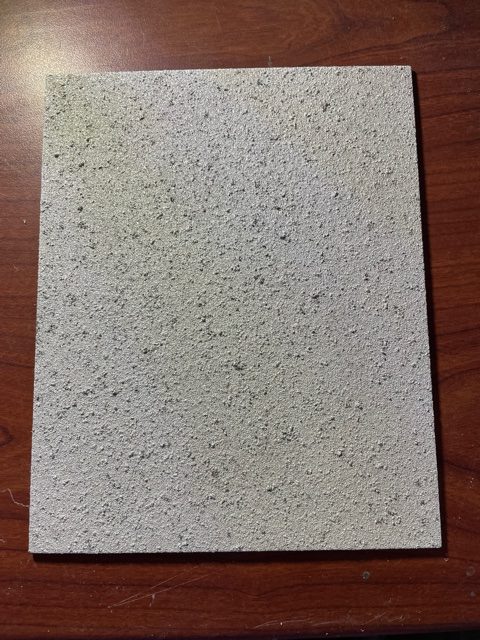

For Non-Skid Applications

- Silicon carbide aluminum composite

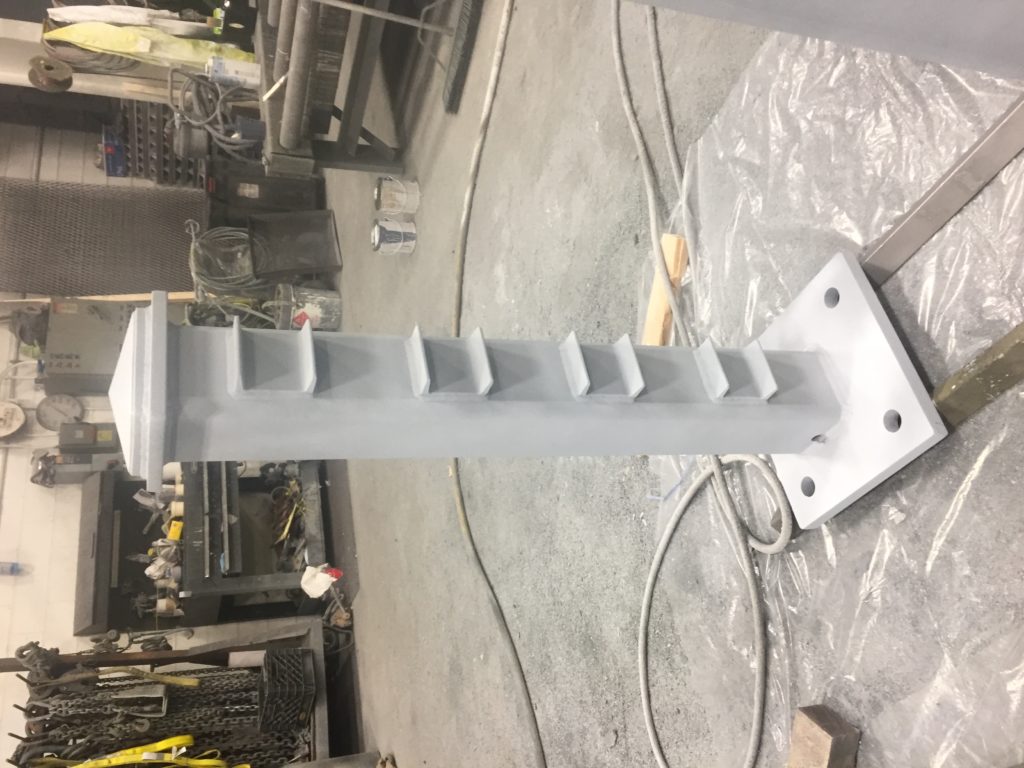

The Thermal Spraying Process

Raw

Abrasive Blasted

Thermal Sprayed

Sealed/Stripe Coated

Finish Coated