The foundation of any successful protective coating system is the surface preparation of the substrate. Industry standards created by SSPC and NACE specify the level of cleanliness and the required texture or profile required to maximize adhesion, performance and the lifespan of the coating system.

As an SSPC-QP3 certified shop, Inter-City Contracting employees are trained to have a complete understanding of these requirements. We will either follow the specified method or use our expertise to choose the correct media to maximize efficiency and level of cleanliness necessary to guarantee the success of your project.

Abrasives available for use on your project:

- steel grit

- steel shot

- aluminum oxide

- mineral slag

- garnet

- crushed glass

- glass bead

- plastic media

Automated Blasting

Specialized equipment delivers effective and efficient blasting with steel shot and grit.

Inter-City Contracting’s “Wheel-a-brator” Rotoblast wheel machine

Inter-City Contracting’s automated table blasting machine

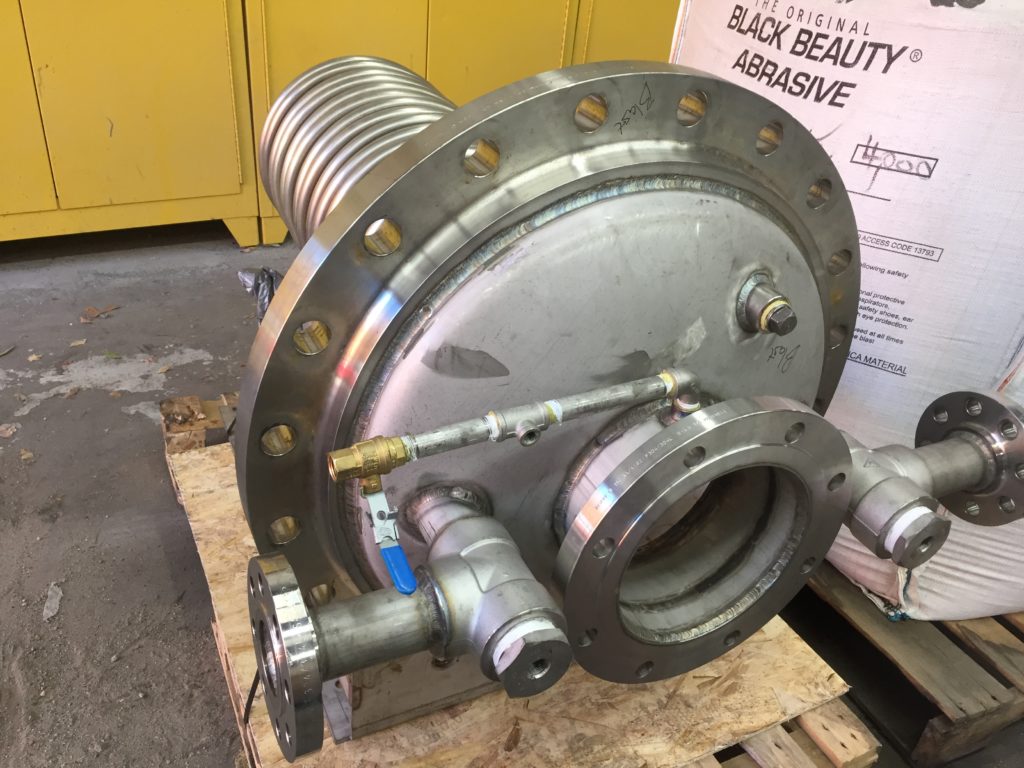

Manual Blasting: Natural Abrasive & Steel Grit

Our experienced employees use handheld equipment in a dedicated blasting area to thoroughly strip components of coatings, corrosion, and other debris.

Specialty Abrasives

Plastic Media

Recycled hard plastic abrasive for paint removal from delicate materials. This is used most often in automotive applications.

Glass Bead

Used most often on stainless steel to remove discoloration and create a smooth texture that hides finger prints.

Click here for more information about the standards for surface preparation